Construction of Parkville/Haymarket Station

| ✅ Paper Type: Free Essay | ✅ Subject: Construction |

| ✅ Wordcount: 5209 words | ✅ Published: 18 May 2020 |

Construction of Parkville/Haymarket Station

Syzna Connect Construction Joint Venture acknowledges the state’s substantial investment in the Melbourne Metro 2 project. In particular the level of planning and programming undertaken to date, to minimize the number of direct interfaces and the packaging of work, to limit the ‘live rail’ working environments. We believe that the programming, sequencing and scope of the multiple work packages provides a robust interface structure that will enhance successful delivery of the all-encompassing project.

We recognize the complex framework of interfaces that exist on a high-profile infrastructure project such as Melbourne Metro 2. Central to our approach is the formation of an enduring partnerships with Department of Transport, which is based on transparency and mutual respect. Our past experience in delivering and collaborating with Department of Transport during the successful completion of the Metro 1 project will be major advantage in delivering this upcoming project. We see ourselves ideally placed to partner long term with Department of Transport, not just for this project, but also for the realization of the State’s broader transport objectives.

In developing our construction approach across the Melbourne Metro 2 alignment, Syzna Connect will apply the following strategies to minimize typical construction-related disruptions and uphold community amenity in and around the construction zone.

Site Analysis

Site Investigations:

The site investigations will be carried out in the initial stage of the project to find suitable locations for the excavation and construction of the tunnels and the station precinct. It will provide information about the underground soil and environmental conditions to ensure that the relevant and the latest information is available for planning phase. Site investigations will include the following activities but are not limited to:

- Geotechnical investigations

- Ground surface surveys

- Groundwater monitoring

- Noise and Vibration

- Service Investigations

- Visual inspections

The geological conditions encountered using geotechnical investigations and using historical borehole from Metro 1 will be methodically investigated to understand the ground conditions for the Parkville station. Existing geotechnical surveys shows Geological formations along the tunnel alignment that ranges in age from Formation siltstone and sandstone laid down approximately 430 million years ago to Coode Island Silt deposited within the last 10,000 years.

The Geotechnical investigation will involve the following steps:

- Stage 1: Site Establishment

- Stage 2: Identification of Utilities and Services

- Stage 3: Geotechnical Drilling

- Stage 4: Well Development

- Stage 5: Groundwater Sampling

Parkville station

Concept Design

The Metro Tunnel 2 will be complex and large project requiring the use of advanced construction techniques. The proposed method continues to be used for constructing road and railway tunnels in major urban environments around the world.

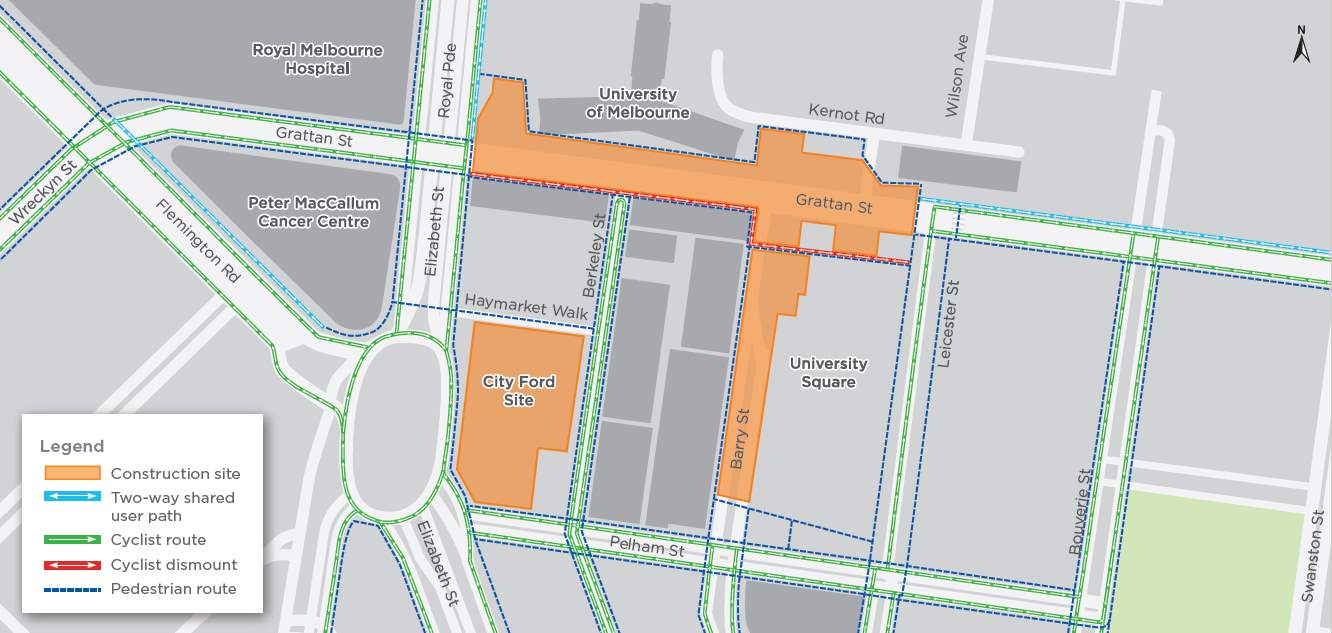

The new Parkville station precinct would be located under the existing City Ford Site, to the east of Elizabeth Street. The station’s platform would occupy the full width of Elizabeth Street and will be directly underneath the City Ford Site. The station would include four entrances, the two main entrances will be directly above the station precinct in the Ford site and the other two will be located at the University of Melbourne (one at the corner of Royal Parade and the other on Grattan Street) and a third entrance located outside the Victorian Comprehensive Cancer Centre (on the opposite side of Royal Parade).

An underground concourse running between the City Ford Site and Grattan Street along Berkeley Street will be constructed. This will provide a direct interchange between the Metro 1 and the proposed Metro 2. This will act as an extension of the existing Parkville promenade and will ensure that there is seamless access for commuters between the two stations. This will also ensure that there is a continuity between the two station precincts better connectivity between the train lines and contribute towards the enhancement of the entire precinct.

The Syzna Connect is proposing to develop a 15 Storey high engineered timber building, which once completed will be Victoria’s tallest engineered timber building. On the surface of the station precinct. The building will be located on the northern section of the City Ford site. The height of the building will be 15 levels considering the height of the surrounding building and in line with council planning regulations. The surface of the station will be transformed into an urban park, with at least 50% of the area allocated to green areas. The construction of this urban space will not only enhance the surrounding but will ensure that the precinct transforms into an attractive place for residents and businesses.

Construction Activities

The Syzna Connect anticipates the construction of the Metro 2 Tunnel and the station will presents many significant challenges, including:

- Excavating large amounts of underground soil and other material, and managing their disposal

- Tunneling under a sensitive area with medical research centers and high-rise building, in addition to excavating on the surface to develop the Parkville station poses significant geotechnical challenges

- Survey of the underground soil condition and excavating through different geological conditions including rock, clay and silt during construction

- Investigation of any existing infrastructure including utilities such as electricity, gas or water pipeline

- Minimizing disruption to existing services, existing road traffic and the tram network

- Mitigating the impacts to adjacent residents and businesses during the construction and operation of the tunnel

Figure: Construction Activities

Syzna Connect which include John Holland has extensive experience in the delivery of such complex projects in Victoria and Acciona has proven record of delivering similar projects globally. Syzna Connect will further identify these challenges in further detail during the RFP phase and we will use our expertise from pas projects and proven methods to successfully overcome these construction challenges.

The station would be constructed using the top down cut cover construction method. The main construction activities at the site would be:

- Temporary construction site occupation

- Early works, including road closures, site establishment and the relocation and protection of utilities

- Piling and excavation of the station box and the twin tunnels using TBM’s & Roadheaders

- Station and platform structural engineering works and station connections across Berkeley street to be completed Parkville station in Grattan Street

- Construction of underground pedestrian entrances and construction of the concourse between the new station and the south side of Grattan street

- Tunnel boring machine pull through and retrieval

- Station electrical, mechanical and architectural fit-out

- Track works and installation of rail systems

- Site remediation, including landscaping and public realm works

- Restoration of Berkeley Street including new road layout.

During construction, Berkeley Street would be closed to traffic between Grattan Street and Pelham Street, with the potential for temporary closures between Royal Parade and Elizabeth Street.

Tunnel Boring Machines

Image Source: Metro Tunnel 1, Melbourne (2019)

Tunnel Boring Machines (TBM) will be used for the construction of the twin rail tunnel. Syzna Connect have significant experience in specifically designed TBM for the excavation of tunnels including the Westgate Tunnel (John Holland) and Legacy Way Tunnel (Acciona) in Brisbane. They TBM’s will be custom designed based on the detailed geotechnical assessment of the ground conditions. Part of the TBM will be assembled on site and the main part of the machine will be assembled underground including the cutterhead and the tunneling operations can commence. The station structure will be constructed while the tunneling of the station takes place. The concrete segments that will be used in the TBM to form a structural ring will be precast in an offsite location and transported to the specified launch location for the TBM. Pressurized steel shield will form an important component of the boring operation as it provides a pressurized environment during excavation to ensure that as the TBM breaks through the diaphragm wall the ground behind the wall and the groundwater stability is maintained and controlled during the tunneling. The temporary steel shield will ensure an efficiency and safety during the initial TBM launch. Syzna Connect will ensure that regular maintenance for the cutterhead to ensure that the excavation is done efficiently.

Syzna Connect will ensure that the latest innovation and technologies from worldwide will be used in the excavation of the tunnel in order to reduce disruption to the Parkville precinct and adjacent environment.

Roadheaders

Image Source: Metro 1 Tunnel, Melbourne (2019)

Syzna Connect proposes to use roadheaders to mine out the caverns for the construction of the new Parkville station. The cutting head of the Roadheader will be specifically designed based on the geological conditions of the ground surface. The Roadheaders will ensure that it is capable of excavating through any soil profile and it will be used in excavating the passageway and platform that will form part of the station.

The machines will excavate around 1500 tonnes of rock each day, and cutterhead is capable of excavating through rocks that are 3 times harder than concrete. Each roadheader will be equipped with highly advanced computer with a mathematically based guidance system used to accurately excavate the cavern.

Construction Methodology

Stage 1: Preparation for TBM and Roadheaders arrival: Royal Parade/Elizabeth St Shutdown for Main Station Box

Stage 1: Preparation for TBM and Roadheaders arrival: Royal Parade/Elizabeth St Shutdown for Main Station Box

1A: Establish Site

1B: Service Relocation

1C: Piling and Preliminary Excavation (i. Main Station Box ii. Berkeley Street)

1D: Bulk Excavation and Base Slab

1A: Establish the Site on City Ford Site

- Install Hoarding, Barriers and fencing

- Establish Pedestrian and cyclist routes

- Tree removal if necessary

- Establish construction facilities

- Excavated the surface up (Assume 500mm thick)

1B: Service Relocation

Image Source: Metro 1 Tunnel, Melbourne (2019)

Services to relocate: Electrical, Gas, Sewer, Stormwater, Telstra & Water

Weekend works with traffic management and road diversions

Our principal objective in relation to utility services is to ensure that no unplanned outage to surrounding areas occurs during construction. This will be achieved by careful planning throughout all stages of design, planning, implementation and commissioning.

Syzna Connect will engage with Dial-Before-You-Dig service as well as with utility service providers and surrounding customer to develop a solid understanding of the existing infrastructure network locations. This will assist us to plan relocations and cutovers in a controlled manner which considers the needs of stakeholders.

Syzna Connect will ensure that stakeholders are kept informed of works affecting their service supply, including any planned outages and alternate supply provisions where relevant. Options and strategies will be developed for residents and businesses that require continuous operation.

1C: Piling and Preliminary Excavation (i. City Ford Site)

Stage 1: Piling

– Weekend piling and installation of sheet piles

– Calculated the no. of piles required based on geotechnical investigation

– 3 rigs – 2 piles per rig per 2-hour shift

– 20 piles per weekend total (43 productive hours)

– Soldier Pile wall

– Drill holes into the ground using an auger to a depth of approximately 32m

– Once the soil and rock are excavated, steel reinforcement cages are lowered into the excavated hole

– The excavated hole is going is then going to filled with concrete and the pile is completed

– Once the piles are constructed, the top layer of concrete is removed and topped with a capping beam

– The capping beam is a steel and concrete beam that ties all the piles together

– It will prevent lateral displacement of the piles during excavation and provides a platform to sit the gantry cranes

Excavation Stage 1: Open excavation to a depth of up to 3m, then a deck is installed over the top

Excavation Stage 2: Excavated soil and rock is loaded into trucks below the deck

Excavation Stage 3: Gantry cranes load excavated soil and rock into trucks in acoustic closures. The soil and rocks are removed from the excavation and lowered into the acoustic enclosure and waiting trucks. Trucks are covered to minimize dust exposure to transport the soil and rock off site.

Stage 2: Shutdown

– Establish Site; Hoarding, barriers, road diversion etc.

– Excavated the surface of the existing site

– First pass excavation (2850 deep) to level E2A: Expose piles (1 Excavator)

– Temporary prop excavation

– Shotcrete walls

– Prep & pour capping beam / Install steel beam to strip piles (assume 900 deep)

Cut and Cover Construction Method

The Parkville station entrance in the Ford Site will be constructed using cut and cover construction technique. We will excavate to a maximum depth of approximately 40 metres using a combination of ‘top down’ and ‘bottom up’ construction methods.

The construction would involve using roadheaders for excavation as well as excavators to dig a large trench or rectangular hole in the ground which will be covered by a concrete deck. Once the deck is in place, surface activity can largely resume as construction works continue below.

During construction of the stations, poured concrete or pre-cast panels are used to form the various levels and internal structures, similar to the construction of the underground basements of high-rise buildings.

1C: Piling and Preliminary Excavation (ii. Berkeley Street)

The following construction steps will be applied in the cut and cover section of the Parkville station:

|

1. Installation of Piling Works |

2. Excavation & Installation of Steel Strut |

|

|

|

|

Bored piles will be excavated to form the retaining wall, before excavation commences. |

Installation of steel struts will provide structural integrity to the retaining wall during excavation. |

|

3. Installation of Decking and Roof Slab |

4. Construction of Station Box |

|

|

|

|

The roof slab is constructed, and decking installed at ground level. The roof slab not only provides a massive support across excavation, it also acts as a noise barrier. |

The next level of slab is constructed, and the process progresses downwards until the base slab is completed. |

|

5. Installation of Side Walls and Base Slab |

6. Backfilling and Reinstatement |

|

|

|

|

The side walls are constructed upwards, followed by removal of the intermediate struts. The access openings on the roof slab are then sealed. |

The soil is then backfilled to the top strut level before the strut is removed. This is followed by backfilling the top of the underground structure and reinstating the surface area. |

Safety & Health

Our Syzna Connect will maintain a strong focus on health and wellbeing of the workforce, passengers and transport users to promote a safe workplace and transport system. Including OHS and social outcomes as an evaluation criterion for procurement, in addition to workforce skills and diversity programs will yield superior project outcomes.

Public safety during construction will be at the forefront of all the construction planning and safety measures be implemented to make movements safe and reliable for users. Work zones will be separated from the public with physical barriers.

Noise, Dust and Vibration

The Melbourne Metro alignment traverses highly populated areas and without the appropriate controls, construction activities have the potential to generate nuisance levels of noise, dust and vibration. Specific construction activities such as TBM and road header operation, piling and excavation have been identified as activities that would generate the greatest impacts particularly in the vicinity of the Parkville and CBD sites.

As part of the plans that Syzna Connect will develop under the Environmental Management Framework (EMF), measure that address the requirements to monitor and measure noise, dust and vibration exposure. The following steps will be taken to address the noise, dust and vibration issues during the construction of the project:

– Undertake vibration and noise modelling in the pre-construction phase to predict impacts communities, resident, structures and sensitive areas such as the hospital, university and health precincts around Parkville.

– Dilapidation Surveys will be undertaken, particularly for the heritage buildings located around the Parkville station precinct.

Based on this assessment, different methodologies can be evaluated based on impact levels and these assessments will be considered when determining the proposed construction methodology. After agreement of construction methodology, a Noise and Vibration Management Plan (NVMP) will be prepared by Syzna Connect to identify potential critical areas and mitigation measures will be proposed. These can include:

– Physical barriers as noise walls or temporary construction sheds to attenuate noise levels

– Procurement of plant and machinery that generates less noise and emissions

– Changes to construction methodology to reduce impact on the adjacent environment

Our design and construct joint venture partners have significant experience minimizing the impact of noise, vibration and dust in urbanized environment. Our past experiences with Legacy Way Tunnel in Brisbane as well as Metro tunnel 1 demonstrates our ability to deliver on these commitments.

Site Logistics optimization

Traffic Management

Syzna Connect acknowledges that much of the work to be undertaken as part of the Tunnel and Stations will have impact on vital infrastructure within Inner north of Melbourne city. We have considerable experience in conducting major CBD construction works in some of the world’s major cities. This experience has taught us that disruption is inevitable, but the level of disruption can be considerably reduced through early engagement with all stakeholders and a process of deliberate planning early in the design and construction stage.

This process involves considering stakeholders disruption in the same way that safety is considered and involves:

– Identifying the major components of disruption and their relative importance through a series of workshops with relevant stakeholders

– Designing as much disruption out of the project as possible

– Planning out as much disruption as possible through modifications to construction staging or methodology

– Using on-site methods to neutralize or mitigate remaining site related disruption

– Where disruption remains unavoidable, using focused stakeholder engagement to educated stakeholders regarding the measure already undertaken, and identify well in advance where disruption may occur during the construction phase.

Spoil Management

Spoil Management on the Parkville station aims to provide safe, reliable and uninterrupted spoil removal to excavation of tunnel and stations while contributing to the wider project goals of safely delivering the project with minimal disruption and minimal environmental impact to the City of Melbourne. The Syzna Connect will develop a Spoil Management Plan (SMP) to manage the safe, environmentally responsible and timely removal of spoil generated from Tunnel excavation.

Spoil Management on the Parkville station aims to provide safe, reliable and uninterrupted spoil removal to excavation of tunnel and stations while contributing to the wider project goals of safely delivering the project with minimal disruption and minimal environmental impact to the City of Melbourne. The Syzna Connect will develop a Spoil Management Plan (SMP) to manage the safe, environmentally responsible and timely removal of spoil generated from Tunnel excavation.

The objectives of the Spoil Management:

Image Source: Metro 1 Tunnel, Melbourne (2019)

– Minimize disruption to trains, trams, pedestrians and cyclists

– Minimal road haulage and truck, trailer demand

– Avoid west gate freeway and western distributor construction area

– Reliable: Zero impact on program – coordination with TBM’s and station excavations

– Net sustainable benefits – reuse of spoil material to positively contribute to another development

– Total expected spoil from Parkville station: 256,090 BCM

Spoil Management – Strategy

– Establish haul routes to avoid areas of major congestion

– Send spoil from east end of alignment south east

– Split short and long-haul methods to reduce road volume

– Use Rail for long Haul to final destination

– Use conveyor belt to transport spoil material to worksites

Our D&C JV partners are familiar with the management of significant amount of spoil removal and management. Acciona experience in deploying an innovative solution by transport spoil from the tunnel via a conveyor belt is an innovative approach that could be replicated during the construction of the Parkville station. The use of conveyor belt significantly reduced the number of vehicle movements through the city, to and from the site. This innovation reduced the impacts on the environment, community as well as having cost and time savings.

Sustainability and Innovation

Syzna Connect recognizes that sustainability also makes sound business sense. Reduction in waste, reuse and recycling contributes to the affordability and value for money of a project. The magnitude of the project and the nature of the works will necessitate the use of significant volumes of construction materials. Syzna Connect intends to draw upon the international experience of the members to implement best practice resource recovery and reuse programs. Through innovation in design and construction, there are a number of sustainability initiative that we may incorporate into our concept design and construction techniques to deliver outcome that go beyond environmental compliance. Some examples include:

– A number of projects across Melbourne have been identified that will benefit in using all surplus spoil and quality fill material excavated from the project, avoiding unnecessary landfilling

– Examining travelling distances for materials supply and for transport of spoil to offsite locations, optimizing travels distances and consequential fuel consumption and emissions

– Contingencies for contaminated spoil treatment that will enable reuse onsite, as well as for offsite projects

– Incorporating energy efficient measure such as a cooled ventilation system, low energy LED lighting in appropriate locations or implementation of an automatic lighting control systems with localized switching

– Reducing greenhouse gas emissions by the specification of an adjustable ventilation system with real time monitoring enabling the unit to reduce energy consumption when ventilation demand is low

Sustainability initiative will be further explored in the RFP phase to ensure that we optimize sustainability outcomes in the delivery of the Tunnel and Stations PPP.

Building Information Modelling (BIM)

The Syzna Connect will explore opportunities to apply the latest available digital engineering/building information modelling (DE/BIM) tools for the implementation of the project. The application of Digital Engineering tools such as BIM will provide better information management throughout the asset lifecycle. The implementation of BIM for the construction phase will ensure that it will enhance safety, improve productivity, reduce risk and improve sustainability.

Parkville Station is going to be a massive construction undertaking and it is imperative that engineers have access to detailed and accurate drawings for project implementation. The D&C Joint Venture will ensure that process is highly automated with the help of BIM/DE tools to speed up production of detailed plans, improve coordination between different disciplines and reduce communication barriers between the design and construction partners. Some of the benefits of the application of the DE/BIM strategy will:

– Eliminate human error by automating the documentation process

– Produce accurate 3D models to create detailed construction plans

– Drives efficiency in the management of infrastructure during the whole asset lifecycle

– Reducing dependency on outsourced drafters and reducing communication barriers

Engineered Timber Building

The Syzna Connect is intending to construct an engineered timber building on the surface of the Parkville Station site. This engineered timber building will be the tallest engineering timber building in Victoria. The final height and form of the building will be decided on further detailed design during the RFP phase and on the regulatory approval from the planning bodies.

The Syzna Connect is intending to construct an engineered timber building on the surface of the Parkville Station site. This engineered timber building will be the tallest engineering timber building in Victoria. The final height and form of the building will be decided on further detailed design during the RFP phase and on the regulatory approval from the planning bodies.

Engineered timber as a sustainable material is gaining popularity due to global focus on reducing greenhouse gas emissions, since energy consumption in the production is significantly lower in comparison to steel and concrete. Timber has been revitalised sustainable construction material but also has major benefits in comparison to traditional construction materials, such as:

-

Materials – Timber is a renewable source of construction material and acts as an important source of carbon storage. The emergence of engineered timber will assist in reducing greenhouse gas in comparison to emission intensive construction materials such as concrete and steel.

Materials – Timber is a renewable source of construction material and acts as an important source of carbon storage. The emergence of engineered timber will assist in reducing greenhouse gas in comparison to emission intensive construction materials such as concrete and steel.

Image Source: Aurecon Office, Brisbane

- Modular Construction – The advantages of the modular construction using engineered timber has been qualitatively assessed and include reduction in construction time; ability to build in remote locations; improved safety; reduction of labor hours; precision of construction

- Prefabrication – Application of Engineered timber in buildings will enhance the construction process because the timber components can be manufactured in a controlled environment, thereby improving build quality and enhancing safety.

- Construction efficiencies – This innovative timber structures allow quick assembly of prefabricated sections, minimizing the construction times thereby reducing costs among other benefits.

Engineered timber is increasingly gaining momentum and it is especially advantageous for high rise residential buildings. The Syzna Connect will investigate further into the design and construction process of the proposed high-rise timber building. We believe this proposal will not only have commercial and environment benefits but will also significantly enhance the appeal of the Parkville station precinct.

Planning Regulations

Our Syzna Connect has demonstrated over many decades and multiple projects in Victoria as well as in wider Australia to comply and operated within the Victorian and Australian legal and policy frameworks environment. The Transport Integration Act (TIA) relevant policies and regulation will be the guiding document in regard to the construction of the Parkville project. In our EOI application for this project, the objectives of the TIA are all closely aligned to the State’s project objectives. The Syzna Connect focus will be to deliver on the following objectives as stated in the TIA:

– Social and sustainable procurement framework

– Towards Zero Road Safety Action Plan

– Environmental Effects Act

– Occupational Health and Safety ACT 2004

– Partnerships Victoria Requirements

We have identified the following main stakeholders that we will be closely working with to achieve aforementioned objectives:

- The Federal and the Victorian government

- Melbourne City Council and University of Melbourne.

- Contractors appointed by the Victorian Government

- Residents and businesses impacted by the project

The next steps of the planning and evaluation phase includes:

- Proposed design of the Tunnel

- Environmental Effects Statements (EES)

- Community engagement and consultation

- Procurement and Contract award

- Finalize planning and environmental approvals

- Commence construction

Syzna Connect is well positioned to exploit opportunities to deliver and maintain the Tunnel and Stations PPP more efficiently, more cost effectively and more expeditiously while maintaining compliance and delivering upon committed policy and project objectives. As market leaders in global infrastructure, Syzna Connect will continue to develop the policy agenda that will deliver the Victorian State.

Project Management

Syzna Connect construction team has extensive background in the project management of complex and significant project and will use the latest techniques and method to ensure Parkville Station is delivered on time and in budget. The collaboration of different organizations and dispersed project teams in Syzna Connect, including John Holland & Acciona as the leading contractor including the design JV which includes WSP and Aurecon will be critical to the delivery of this high-profile infrastructure project. A centralized approach will be applied to ensure that all teams are on the same platform to improve efficiency and enhance collaboration during project.

Syzna Connect have identified mainly 3 software platforms for the management and delivery of the project:

Platform 1: Cloud based software to deliver collaborative project delivery, including design & construction coordination, field management, and project controls for example Aconex.

Platform 2: Cloud/On-premise based software for project scheduling, planning, portfolio and risk management and the secure, online management of construction documentation, for example Primavera.

Platform 3: Cloud based software for payment management and supply chain financing, for example Textura.

Contract Administration System

Syzna Connect have demonstrated considerable experience in the successful contract administration process for major infrastructure projects throughout Victoria as well as nationwide. The Joint Venture intends to have a robust contract administration system in place to ensure the delivery of this critical project. Some of the responsibilities that will be assigned to the contract administration team during the RFP and delivery phase is as follows:

– Preparation, issue, organize and recommendation for subcontractor’s award with detailed input from the construction, engineering and procurement team.

– Managing the engagement process such as the contract execution including compliance with insurances and WHS regulations

– Receive and process the subcontract claims and final accounts in accordance with contractual obligation and relevant legislation

– Support the review and response to all contractual correspondence

– Maintain all necessary registers, vendor and contractual documentation, and non-disclosure agreements.

– Ensure the above steps are carried out in line with statutory obligations along with any Project policy, workflow & procedure.

Communication Standards

Syzna Connect has three core strategies to ensure that the highest standard of communication is achieved via the following strategies:

Syzna Connect has three core strategies to ensure that the highest standard of communication is achieved via the following strategies:

- Community and Stakeholder Engagement Program

- Reputation and positioning Program

- Workforce Commitment Program

Syzna Connect will allocate a dedicated team responsible for delivering on the project objectives by engaging with our stakeholders and Department of Transports at every stage to ensure a successful completion of this critical infrastructure project.

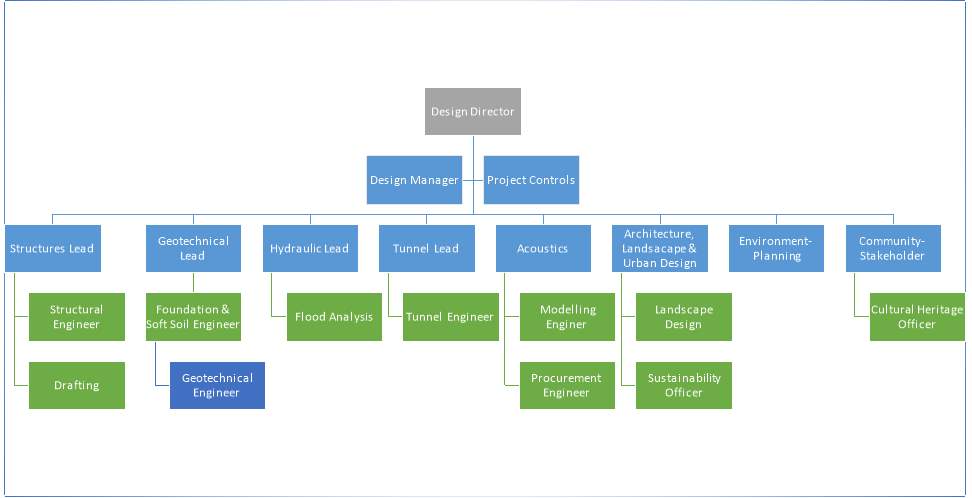

Construction JV Organization Chart

Design JV Organization Chart

References

- Shemery, A. and Hampson, K. (2019). Digitally Engineering the Future – Opportunities for VicRoads. [online] Sbenrc.com.au. Available at: https://sbenrc.com.au/app/uploads/2018/09/P2.46VicRoadsCaseStudy-FINAL.pdf [Accessed 22 Aug. 2019].

- Metrotunnel.vic.gov.au. (2019). Cut and cover | Building the tunnels and stations | Construction | Metro Tunnel. [online] Available at: https://metrotunnel.vic.gov.au/construction/building-the-tunnels-and-stations/cut-and-cover [Accessed 22 Aug. 2019].

- Johnston, M. and Johnston, M. (2019). Benchmark Awards 2019 Finalists: Aurecon Jacobs automates digital tunnel drawings. [online] iTnews. Available at: https://www.itnews.com.au/news/benchmark-awards-2019-finalists-aurecon-jacobs-automates-digital-tunnel-drawings-518367 [Accessed 22 Aug. 2019].

- Metrotunnel.vic.gov.au. (2019). Roadheaders | Building the tunnels and stations | Construction | Metro Tunnel. [online] Available at: https://metrotunnel.vic.gov.au/construction/building-the-tunnels-and-stations/roadheaders [Accessed 22 Aug. 2019].

Cite This Work

To export a reference to this article please select a referencing stye below:

Related Services

View allDMCA / Removal Request

If you are the original writer of this essay and no longer wish to have your work published on UKEssays.com then please click the following link to email our support team:

Request essay removal